Validation scheme

For each vehicle type, consider both cost and effort, comprehend whole requirement, plan an optimized validation scheme.

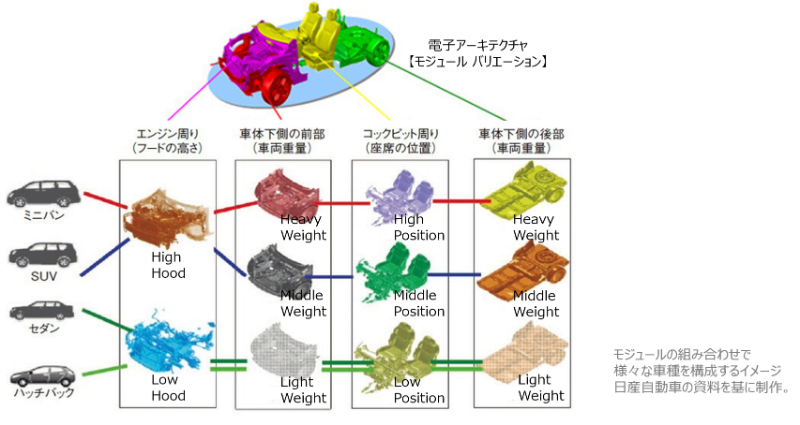

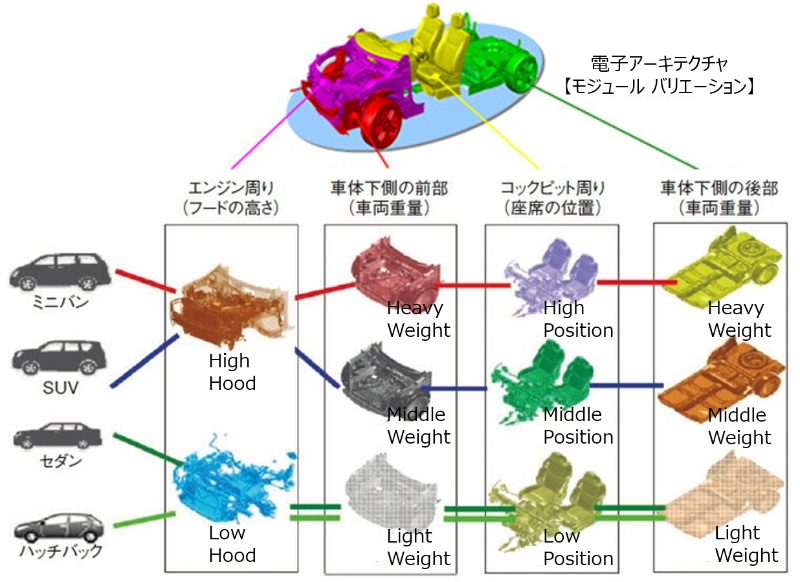

The latest production cars are equipped variety of parts and systems. Not all they are new feature. Most development are based on modifying existing modules by utilizing data and increment design. At that time, we provide vehicle validation support to consider existing modules fit production car.

モジュールの組み合わせで様々な車種を構成するイメージ。

日産自動車の資料を基に制作。

For each vehicle type, consider both cost and effort, comprehend whole requirement, plan an optimized validation scheme.

To finalize Production implementable quality, manage the problems and collaborate with other departments.

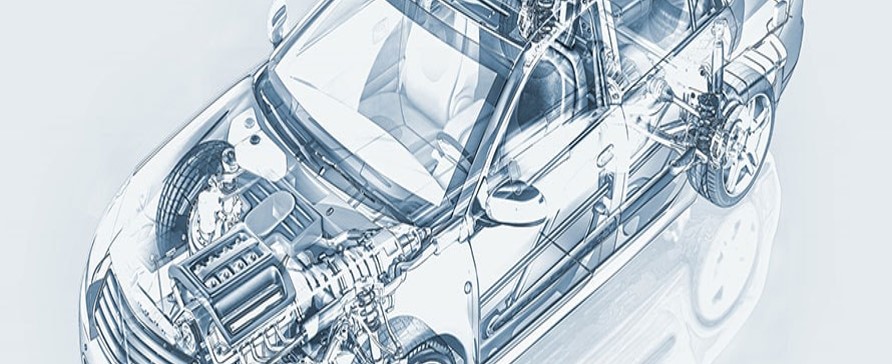

An Automobile contains a bunch of electronic devices. Durability and reliability are needed for the electronic devices, even if devices are exposed to high temperature and oil and salty water, tiny space and high vibration. These onboard devices will be tested from variety of point of view to ensure reliability to make them work properly.

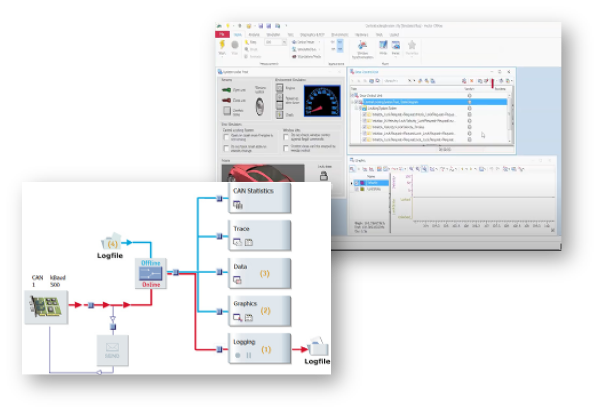

Capture CAN signal on the vehicle, perform analysis. Confirm specific devices or vehicle work as expected by using CAN analysis tools like CANalyzer. Consider the software quality is enough or not to implement production car.