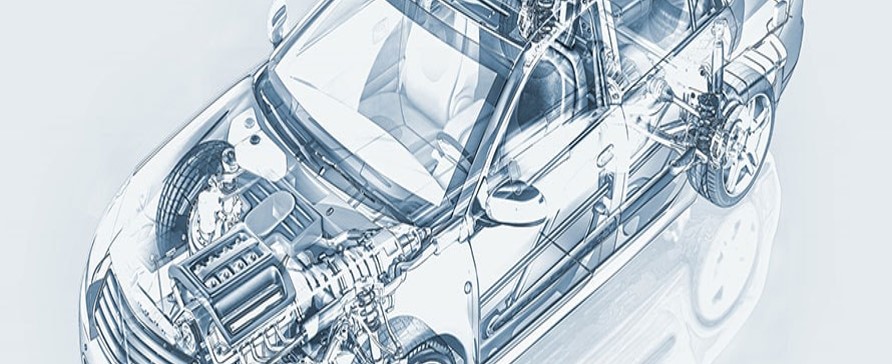

Model based design/CAE analysis

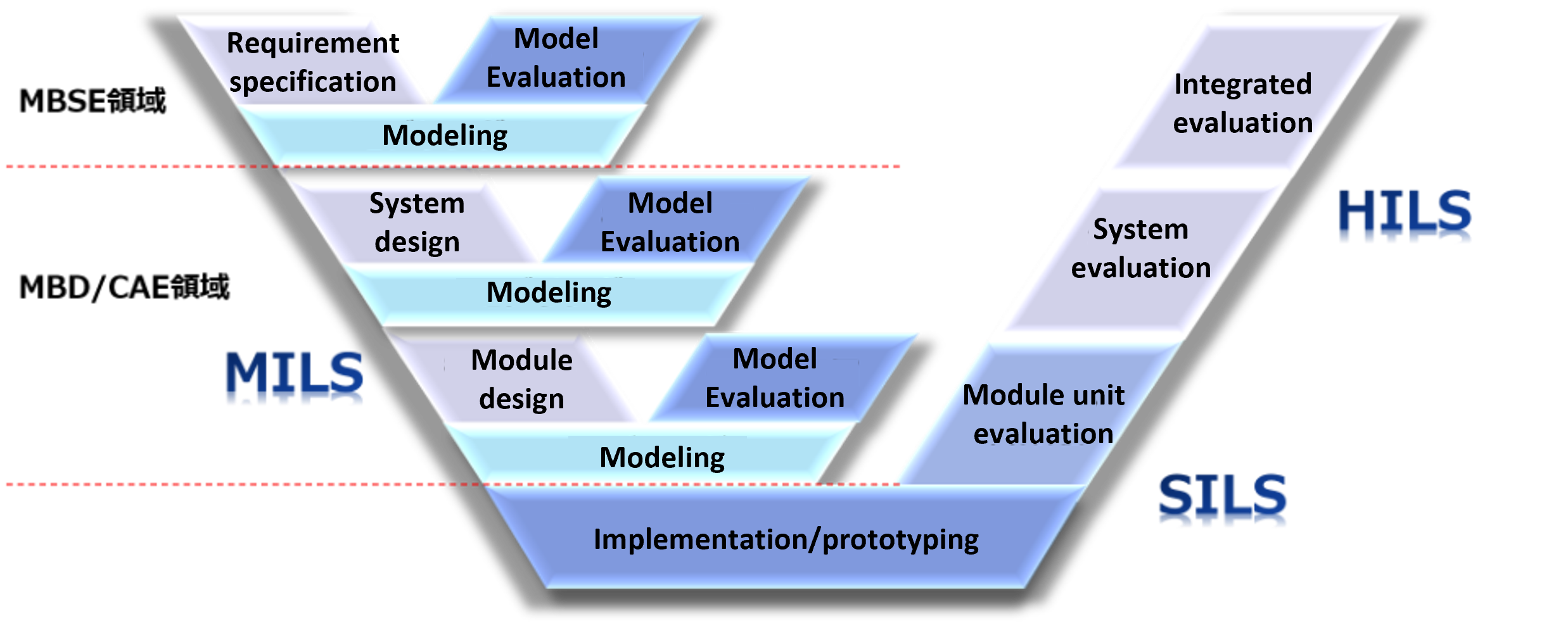

Recently, “MBD” is spreading rapidly with development of In-Vehicle systems. MBD is the method that create the model as “Working Specification”. By using simulation capability of the model, development period can be drastically shortened and improve the quality of the software. We provide the service as the customer needs.

Fields of business

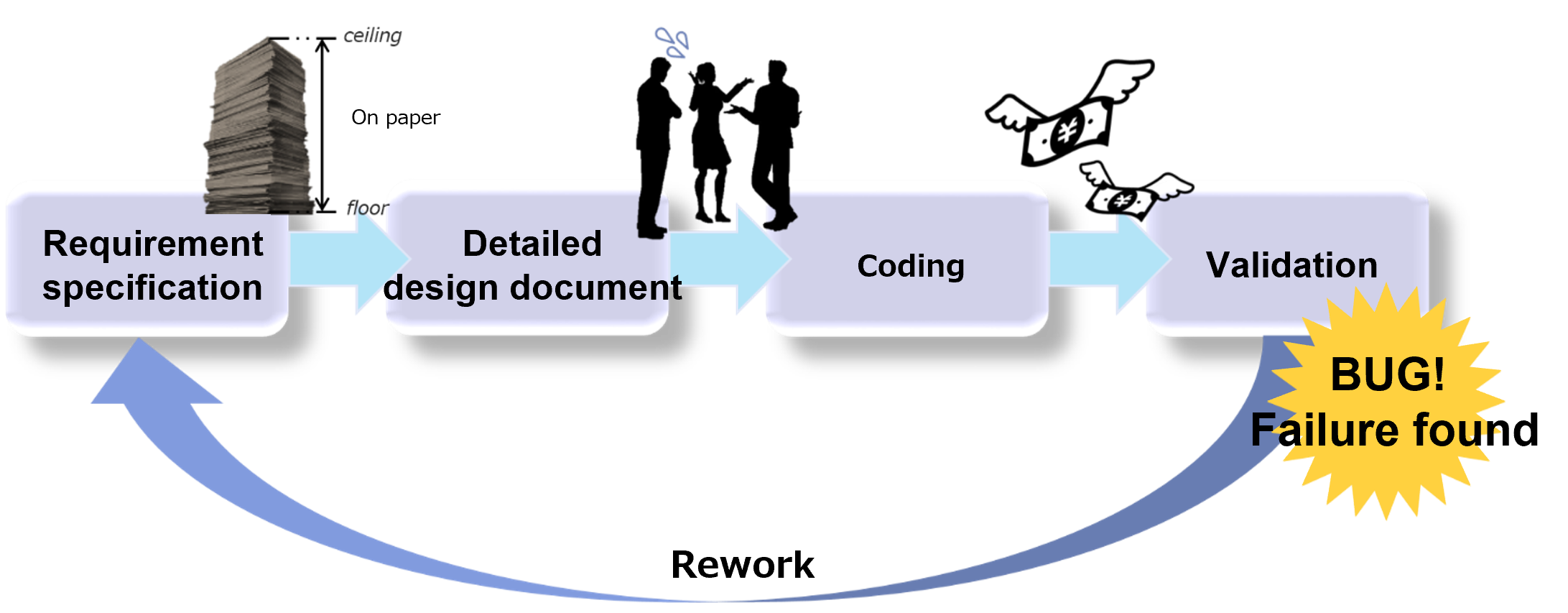

From existing development process to MBD/CAE

In case of existing development method, actual device is built referring the specification created on the desktop. Failures had been found during building the actual device. Reworking had been needed for each failure.

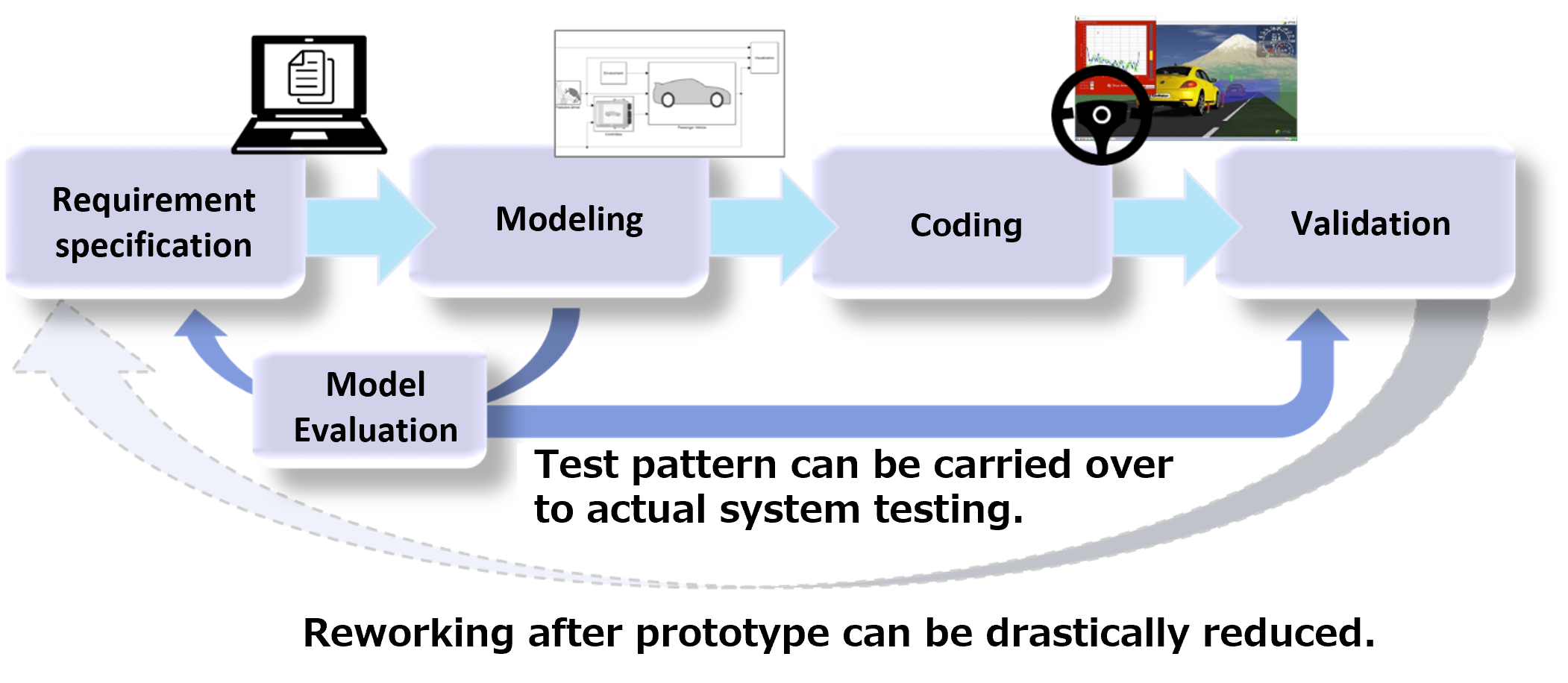

In case of MBD, control model will be created on the time of specification is fixed.

The model can be tested before coding process.

Due to reason above, most failures can be found and fixed in the modeling phase.

The failures after software implementation will be reduced as possible.

Conventional problem and the Profit of MBD and CAE

1.Validation cannot be done without actual device. Reworking process was needed for every failure.

![]() The failure of specification can be recognized and fixed before creating actual device.

The failure of specification can be recognized and fixed before creating actual device.

![]() The work load can be drastically reduced due to the reworking process can be minimum.

The work load can be drastically reduced due to the reworking process can be minimum.

2.Huge amount of specification have to be read and understood to develop the software to implement.

![]() The model becomes the working specification, misreading cannot be happened and development goes smoothly.

The model becomes the working specification, misreading cannot be happened and development goes smoothly.

![]() The code can be generated automatically from the model.

The code can be generated automatically from the model.

3.Test items that cannot be apply physically on actual devices exist.

![]() Reliability improves by the simulation with variety of situation.

Reliability improves by the simulation with variety of situation.